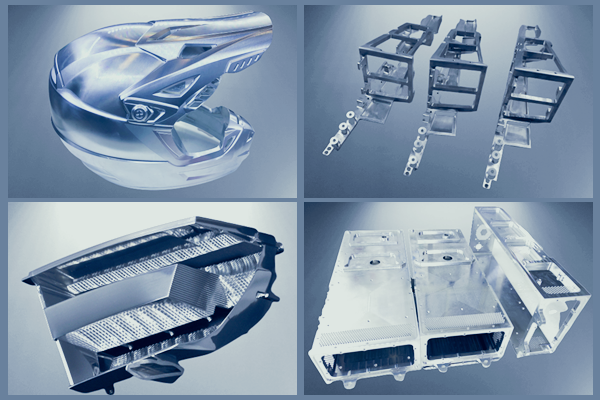

The Benefits of Sheet Metal Prototyping and Aluminum Prototypes

In today’s fast-paced product development world, sheet metal prototyping has become essential for creating reliable and durable components. Whether it's for electronics, automotive, or industrial products, this technique allows engineers and designers to test the functionality, fit, and aesthetics of their designs without committing to full-scale production. One material that stands out for prototyping is aluminum, offering a variety of advantages. Why Choose Aluminum for Prototyping? When it comes to aluminum prototypes , they are popular for a reason. Aluminum is lightweight yet strong, corrosion-resistant, and relatively easy to work with. This combination of properties makes it perfect for creating precise, intricate parts. Additionally, aluminum’s affordability and availability allow manufacturers to prototype at a lower cost without compromising on quality. For those looking to achieve rapid turnaround, sheet metal prototyping with aluminum is an excellent option. The use...