Exploring the Advantages of Aluminum Prototypes

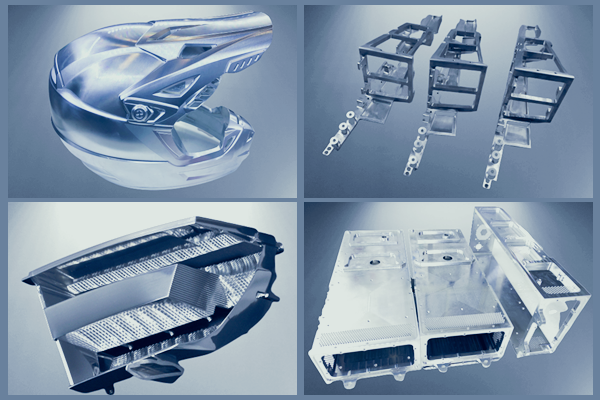

Aluminum Prototype has revolutionized the field of product development, offering numerous advantages over traditional materials. With their exceptional properties and versatility, aluminum prototypes have become a preferred choice for designers and engineers alike. In this blog post, we will delve into the key benefits of aluminum prototypes, shedding light on their impact on the product development process. Aluminum, renowned for its lightweight nature, makes it an ideal choice for creating prototypes. Its low density ensures easy handling and transport, facilitating rapid iteration and testing. Additionally, aluminum prototypes exhibit an excellent strength-to-weight ratio, ensuring durability while minimizing material usage.

Aluminum prototypes have emerged as a game-changer in the realm of product development, offering a host of advantages. Their lightweight nature, exceptional strength-to-weight ratio, and precision machinability contribute to the creation of functional and realistic prototypes. Moreover, the cost-effectiveness and superior performance of aluminum prototypes make them an attractive option across various industries. As the demand for efficient and reliable product development processes grows, aluminum prototypes continue to shape the future of innovation.

Sheet Metal Prototyping: Revolutionizing Product Development

Sheet Metal Prototyping is a game-changing process that has transformed the landscape of product development. This versatile technique offers engineers and designers the opportunity to test and refine their ideas before committing to large-scale production. By leveraging the flexibility, speed, and cost-effectiveness of sheet metal, businesses can accelerate innovation and gain a competitive edge in the market. In this blog post, we will explore the key benefits of sheet metal prototyping and its impact on various industries.

Sheet metal prototyping has revolutionized the world of product development. By providing rapid iterations, precise testing, and optimized production processes, this technique empowers businesses to innovate faster and produce superior products. Its impact spans various industries, enabling advancements in automotive, aerospace, consumer electronics, and beyond. As technology continues to evolve, sheet metal prototyping will undoubtedly play an increasingly crucial role in shaping the future of manufacturing.

Comments

Post a Comment